Dr. Li Chen is a Professor of Operations, Technology and Information Management and Breazzano Family Term Professor of Management at Samuel Curtis Johnson Graduate School of Management at Cornell University. Dr. Chen’s research interests concern supply chain management, operations strategy, and Bayesian methods for predictive and prescriptive analytics. He has published research works in top journals in the operations management field, such as Management Science, Operations Research, and Manufacturing, Service and Operations Management. Prior to joining Johnson School, Dr. Chen was an Associate Professor of Business Administration at The Fuqua School of Business at Duke University. Before his Duke appointment, Dr. Chen spent four years at TrueDemand Software, a supply chain software company in Silicon Valley, where he was the cofounder and lead scientist of the company. Dr. Chen obtained his PhD in Management Science and Engineering from Stanford University in 2005.

Supply Chain AnalyticsCornell Certificate Program

Overview and Courses

Supply chain analytics is an essential tool for organizations to improve efficiency and gain a competitive advantage. How can you optimize this area of your business?

In this program, you will be introduced to analytical methods for supply chain demand forecasting, inventory optimization, and production capacity allocation. You will also have the opportunity to explore advanced topics in supply chain finance, coordination strategies, and sustainability. These topics will be accompanied by practical Excel tools and activities designed to help you apply the concepts to your role and beyond. By bridging the gap between concepts and practice, you will set your team up for success in today’s ever-changing market.

To be successful in this program, fundamental Excel skills (writing simple formulas and creating basic graphs) and basic knowledge of statistical analysis are essential.

The courses in this certificate program are required to be completed in the order that they appear.

Course list

Supply chain analytics are everywhere. Consider the similarities between a grocery list and a demand forecast: Before going to the store, you note which groceries you already have in your home. Next, you think about how much of each item you used in the past. Based on this information, you can predict how much of each item you need to purchase. In this micro example, you are acting as a supply chain analyst.

As you look at the implications of a larger-scale supply chain analysis, you'll grasp the complexity that organizations face in making accurate demand forecasts. When grocery shopping, if you make mistakes, you can just go on another trip and correct the purchase. In business situations, however, a mistake could mean a significant loss. In this case, you want to make decisions in a scientific and proven way.

In this course, you will measure performance based on an existing dataset. You will then determine the best forecasting method based on the given data. Finally, you will expand the application of this data by calculating a forecast for future demand and considering holistic approaches for mitigating risk, applying practical skills to incorporate into your future work with supply chain analytics.

- Jul 16, 2025

- Sep 24, 2025

- Dec 3, 2025

- Feb 11, 2026

- Apr 22, 2026

Inventory is everywhere; you can find inventory in your refrigerator, pantry, and on the shelves of grocery stores. Yet there's also more "invisible" inventory in delivery trucks, shipping containers, and distribution centers. Managing inventory along the supply chain can be complicated. For businesses, keeping the right amount of inventory in supply chains is critical for maximizing profit.

In this course, you will discover how to determine the optimal inventory level for a supply chain location. First, you will explore the trade-off between inventory and customer service. You will then examine how to assess the cost performance of a single supply chain location and the trade-off between inventory holding and shipping costs. You will also determine the cost performance of a network of supply chain locations. Finally, you will discuss improving the supply chain cost performance by inventory pooling.

The following course is required to be completed before taking this course:

- Forecasting Supply Chain Demand

- Jul 30, 2025

- Oct 8, 2025

- Dec 17, 2025

- Feb 25, 2026

- May 6, 2026

For products with a short life cycle — including items like fresh food, fashion, and even high-tech products — supply chain managers often have to make a one-shot decision for production quantity to meet the demand over the entire selling season, which could vary from a day to a few months.

In this course, you will examine how to determine the optimal production quantity for products with a short life cycle, assuming there is no resource capacity constraint. You will then explore how to optimally allocate the production capacity among multiple items when there is a limited resource capacity available. You will also discover how to determine the optimal production sequence if more accurate demand information can be obtained at a later time. Finally, you will discuss how to improve supply chain efficiency through various operations strategies, adding to your toolkit of practical knowledge for your organization and beyond.

The following courses are required to be completed before taking this course:

- Forecasting Supply Chain Demand

- Optimizing Inventory Management

- Aug 13, 2025

- Oct 22, 2025

- Dec 31, 2025

- Mar 11, 2026

- May 20, 2026

Supply chain analytics goes beyond managing the flow of information and products along the supply chain; it's also about managing the cash flow, people, and ecosystem along the supply chain. This approach to management is known as the profit, people, and planet triple bottom line. Supply chain cash flow, or profit, concerns payments and trade financing between supply chain parties. The people element of supply chains concerns managing relationships with your customers and suppliers. Finally, the ecosystem, or planet, element of supply chains concerns the environment where the supply chain operates. You therefore need to be aware of your competition, government regulations, and your supply chain's social and environmental impact in order to properly balance all three and gain a competitive advantage.

In this course, you will explore how to measure and improve supply chain cash flow efficiency. You'll also discover design strategies to achieve coordination with your partners and achieve sustainability in the supply chain.

The following courses are required to be completed before taking this course:

- Forecasting Supply Chain Demand

- Optimizing Inventory Management

- Optimizing Production Capacity Allocation

- Aug 27, 2025

- Nov 5, 2025

- Jan 14, 2026

- Mar 25, 2026

- Jun 3, 2026

How It Works

- View slide #1

- View slide #2

- View slide #3

- View slide #4

- View slide #5

- View slide #6

- View slide #7

- View slide #8

Faculty Author

Key Course Takeaways

- Calculate a forecast to address demand variability

- Determine optimal inventory level and assess supply chain costs to improve overall performance

- Optimize production capacity and allocation for short-cycle products to improve supply chain efficiency

- Improve cash flow efficiency and design strategies to achieve supply chain coordination and sustainability

Download a Brochure

Not ready to enroll but want to learn more? Download the certificate brochure to review program details.

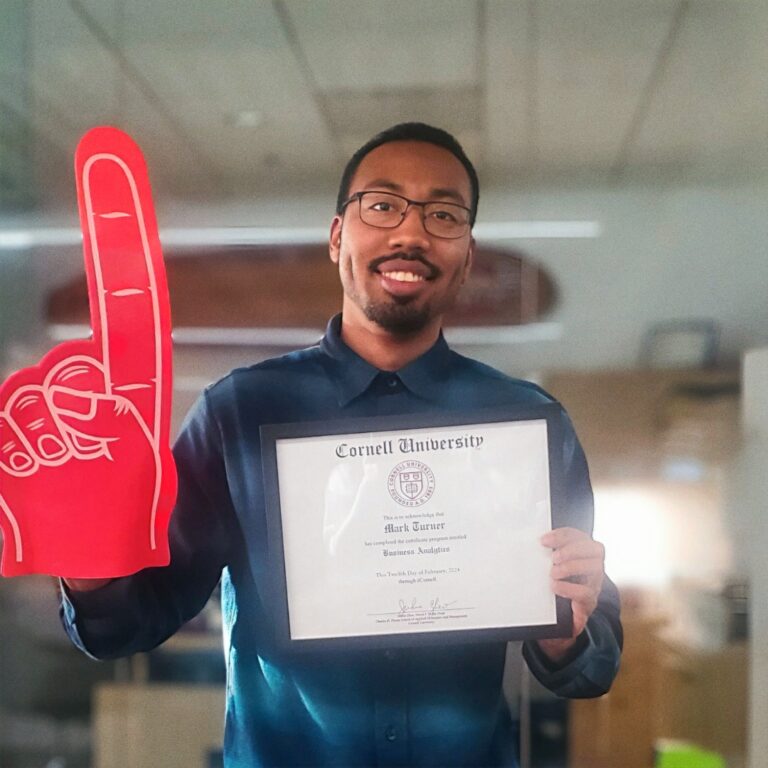

What You'll Earn

- Supply Chain Analytics Certificate from Cornell’s SC Johnson College of Business

- 56 Professional Development Hours (5.6 CEUs)

Watch the Video

Who Should Enroll

- Individuals seeking to increase skills in supply chain strategy

- Operations analysts

- Market analysts for consumer and industrial products

- Consultants seeking supply chain knowledge

Request Information Now by completing the form below.

Supply Chain Analytics

| Select Payment Method | Cost |

|---|---|

| $3,750 | |